Our Product

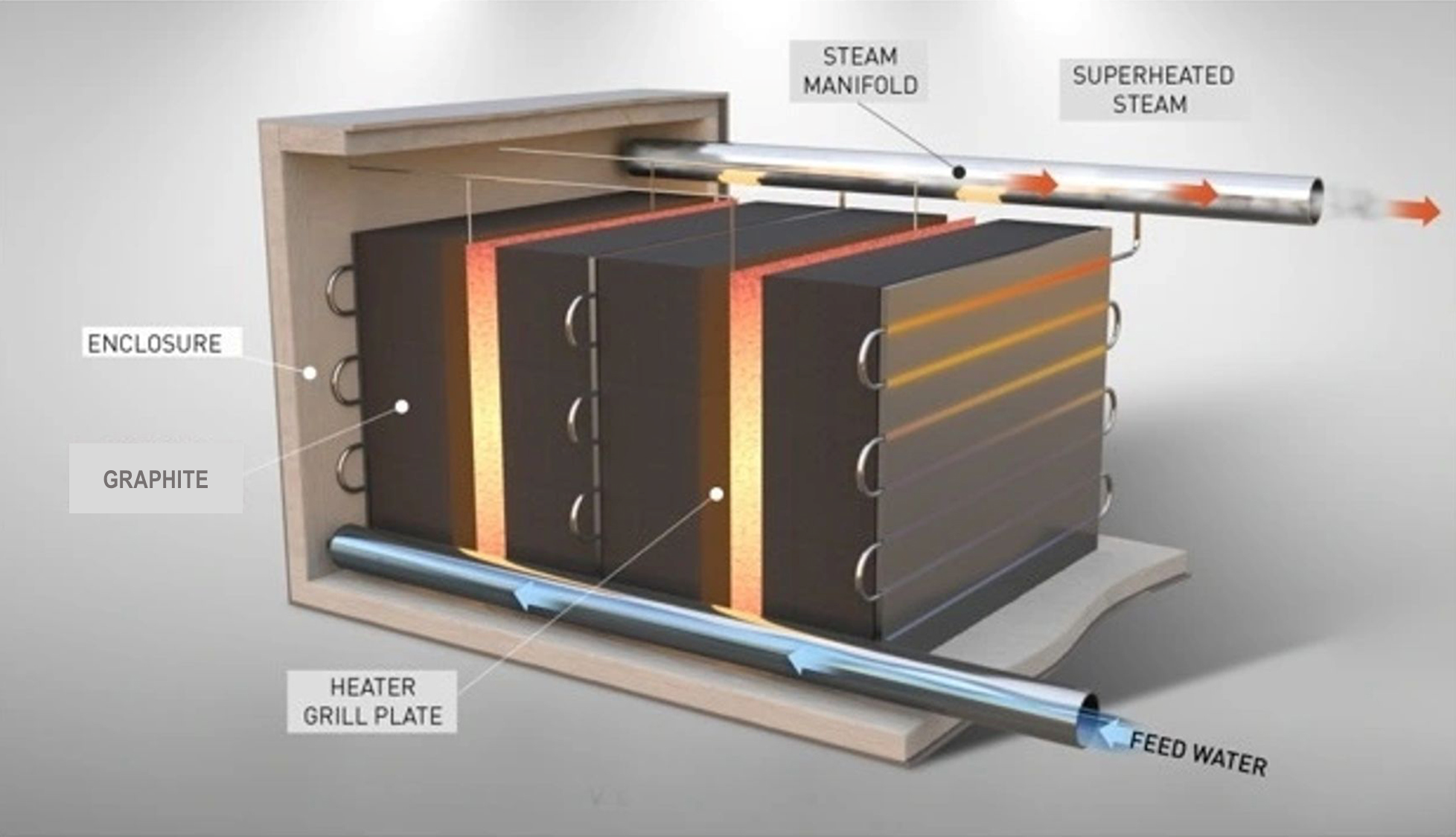

Our product is a novel energy collector, TWEST, which constitutes the building block at the heart of our power plant conversion solution. TWEST is a compact “all in” standardized module that does not require any additional auxiliary equipment, external heat exchangers or additional working fluids. The compact, modular design allows scaling up to match the required storage capacity of a project. The use of existing equipment and infrastructure, particularly in plants scheduled for decommissioning, minimizes investment cost and the modular approach makes our solution very adaptable to different configurations.

When charging, each TWEST module converts surplus electrical energy during periods of low demand into heat using high energy density storage materials. When discharging, the system returns the stored energy in the form of superheated steam to power the legacy steam turbines and generators. Our design can be designed to be charged to full storage capacity in as little as one hour with near 100% conversion of electricity to heat and has the flexibility to discharge from a few hours to 8+ hours as a long duration energy storage solution. Other key benefits include negligible degradation in performance, no depth of discharge issues and long life. Thanks to these advantages, our solution will be among the most competitive in terms of levelized cost of storage.

TWEST Key Advantages

Environmentally Benign

Made of abundant, safe and recyclable materials.

Safe

The design is inherently fail-safe, maximum temperature is limited. The process is not chemically active and poses no fire risk

Long life

Our system is designed for 30 years. No issues related to degradation or depth of charge. Storage material safe and remain stable throughout their life cycle

Compact design with high energy density

This makes it the most suitable utility scale storage with a footprint 2 to 5 times smaller compared to all other storage systems

Scalable modular design

All-in modular design without the need for additional external equipment such as heat exchangers. Easy integration and minimum disruption to existing plant. Can be easily scaled up thanks to modularization concept

Lower capital cost

Our system maximizes use of existing equipment and infrastructure (all but coal related equipment and mine)

Supports grid stability

By using synchronous generators, better able to provide voltage and frequency support compared to batteries

Socio-Economic Benefit

By using existing, potentially stranded assets and by retaining jobs, our technology can help local economies transition to clean energy.

Fast implementation

Due to the simple, easy to integrate technology, our technology allows faster deployment. A typical time to market (from order to commercial operation) is estimated to be less than 18 months.