Thermal energy storage, production of CO2 free electricity in thermal power plants

E2S Power, a joint venture between Swiss SS&A Power Group and German company WIKA, presented the innovative thermal energy storage TWESTTM, which provides a solution for intermittent production from renewable energy sources and conversion of thermal power plants to CO2 free operation. The E2S Power thermal energy storage technology has been validated in the E2S demonstration facility in Belgrade and enables the transformation of the coal power plants into green energy storage facilities and producers of CO2 free electricity.

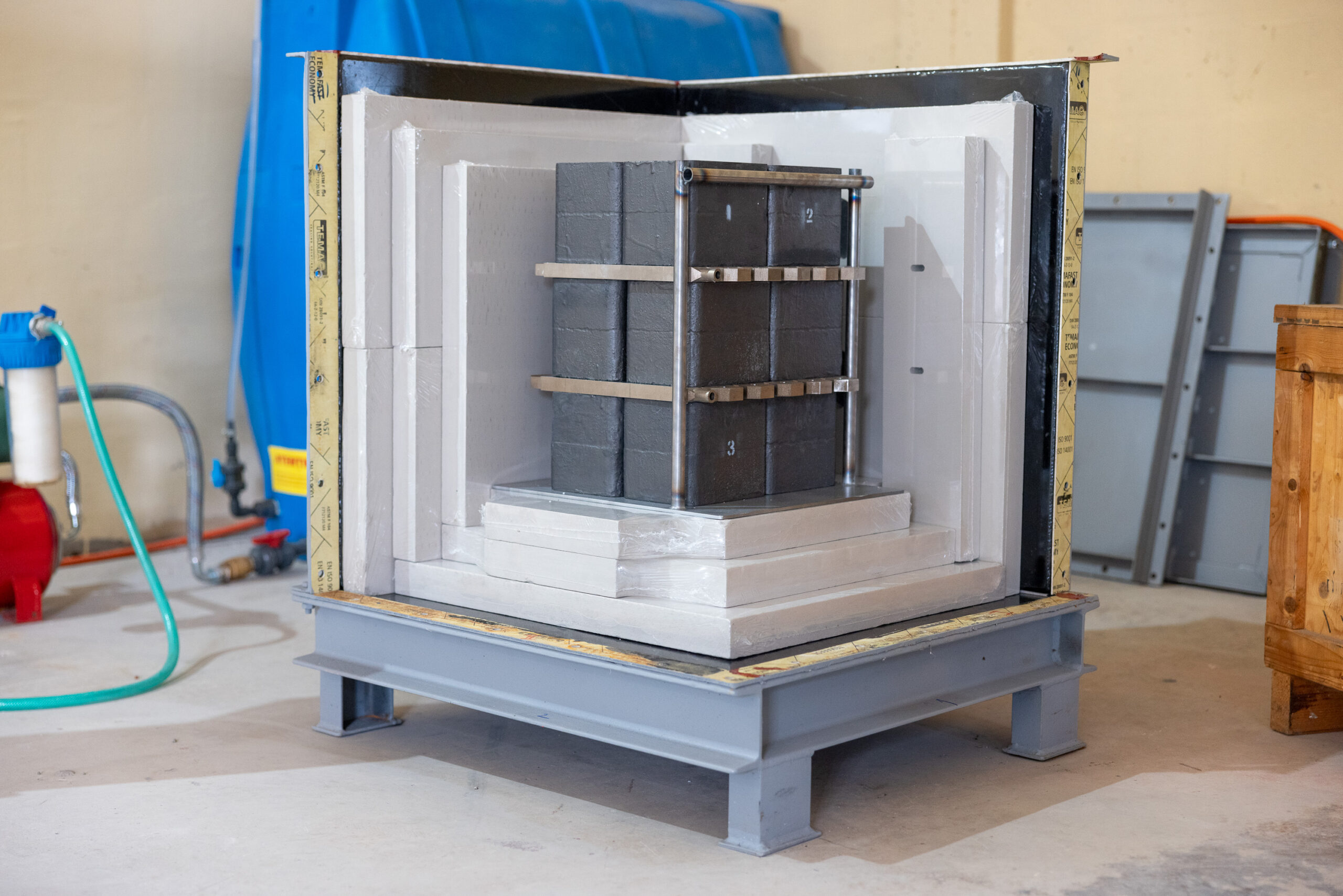

In the test performed, the system was charged the previous day and the heat stored was used to generate steam, also demonstrating the capability to maintain temperature for a long period of time.

E2S Power is currently developing three pilot projects in Europe and the USA. E2S Power is also in discussions for several commercial scale projects in Europe, US and Canada.

The implementation of the solution for the existing coal power plants would involve the installation of the Traveling Wave Energy Storage Technology (TWESTTM) system that includes in one module the following: electric radiating heaters, MGA storage blocks, and steam generators. The system stores energy from wind farms or solar power plants in the form of heat and when necessary the heat is converted into steam to run existing steam turbine generators to produce electricity.

“Our solution combines heaters, storage, and steam production in one compact unit. Electricity is converted to heat and back to electricity without using air or other media,” said Fabrizio de Candia, E2S Chief Operating Officer.

He added that it is very important the solution transition coal power plants to clean energy utilizing existing infrastructure and employees.

The solution is based on traveling wave principle to maintain a constant steam temperature, and Miscibility Gap Alloys (MGA) a storage medium with superior energy density compared with other thermal energy storage materials.

„The system is based on the traveling wave principle utilizing two sets of storage blocks. During the charging process the first set of storage blocks is heated to a very high temperature of 700 degrees Celsius, while the second set is heated to the temperature required by the steam turbine. In the discharging process, steam is initially generated in the first set of blocks at the temperature close to 700 degrees Celsius and then is cooled down by the second set of blocks to the turbine inlet temperature. During the process the heat is moved in the form of traveling waves from the hotter to the moderate thermal storage blocks“, said Dr. Sasha Savić, E2S Power Chief Executive Officer.

Energy storage materials are based on Miscibility Gap Alloys (MGA) which have been developed by Australian partner MGA Thermal. These blocks consist of graphite and aluminium, the materials that have a long life, are abundant, safe and recyclable.